We offer precision machine processing of various materials with great cost effectiveness

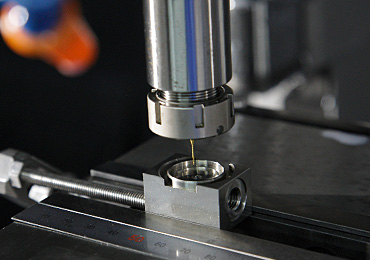

We offer precision machining of parts with a complex/difficult-to-machine shape for various materials such as aluminium and stainless steel. With our advanced process planning ability, and the operation of multiple CNC lathes and machining centers or combination of them contribute to a high productivity with great cost effectiveness better than when a multifunctional machine or five-axis machining center is used. Also, we can deal with a integrated production from precision machining to product assembling.

Advantages of precision machining

For manufacturing of various industrial parts with more severe requirements, we offer micron-order precision machining

From prototyping to mass production of various industrial parts, we realize micron-order precision machining. For example, we can produce industrial robot parts with geometrical tolerance of 10μm by our high-level process planning approach and using CNC lathes and machining centers with original accurate cutters and jigs.

We also provide a wide variety of highly difficult machining such as burr-free drilling of a micro cross hole of φ0.4 diameter and circular machining of medium size (approx. φ100) ring-shaped thin materials.

From development/prototyping to the medium lot and mass production, we realize an integrated production at a first-rate cost effectiveness

We can provide a comprehensive support applying original VA/VE proposal from development and prototyping to the medium lot (50-500 pcs.) and mass production (over 500 pcs.). Concurrent operation of 30 high performance CNC lathes and 9 machining centers enables a significant lead time reduction.

The use of CNC lathes/turning centers and machining centers in combination achieves a high productivity better than that of a multifunctional machine or five-axis machining center. For the medium lot, in particular, we realize an integrated production at a first-rate cost effectiveness.

We offer precision machining of parts with a complex /difficult-to-machine shape for various materials such as iron, brass, and titanium as well as aluminium and stainless steel

Besides aluminium and stainless steel, we can process a wide variety of materials including iron, brass, titanium, and hardened steel. For shape of objects, we can deal with machining of complex shape/hard-to-work materials such as round, rectangle, or odd-shape objects. For object size, we can deal with the following size: φ0.5 to φ1000×300 for a round object; 5×5×5 to 2500×1800×20 for a rectangle (may use our production network).

Examples of order

- Semiconductor production equipment parts

- Hydraulic/pneumatic equipment parts

- Welding robot parts

- Transfer robot parts

- Injection machine's peripheral device parts

- Pressing machine parts

- Fluid machinery parts

- Printing machine parts

- Machine tool parts

- Automobile parts

- Medical equipment parts, etc.

*We respond to any precision machining needs from various industries to achieve high-precision high-quality manufacturing at reasonable proper cost.

Assembly service

We offer a one-stop service including assembly of precision machining parts for different industrial equipment

We can give 100% quality assurance for assembly of major manufacturers' products

From inventory control to shipping agent service, we supports business outsourcing (OEM)

We provide a comprehensive service including assembly service after precision machining. We can offer, for example, a one-stop service from parts material procurement to assembly of components of equipment developed by a leading manufacturer. In addition, we support business outsourcing activities (OEM) including a shipping agent service at major manufacturers' request, using our original real-time inventory control system.

We respond to needs of the medium lot production (50-500 pcs.) at a first-rate cost effectiveness.

If you consider the medium lot production of precision parts:

Our expert engineering staff thoroughly familiar with precision machining practice will hear customer needs. Based on broad knowledge and long experience, we will design appropriate process. Using efficient machining techniques, we offer the medium lot precision machining service (50-500 pcs.) at the most competitive cost in the industry.

Nakano's precision machining service is suitable for the industries listed below

Our precision machining service has served for a number of customers in over 20 industries. Our service is suitable for manufacturers who are planning to outsource the medium-lot machining of high precision, high quality parts.

- Semiconductor related system manufacturing industry

- Industrial robot manufacturing industry

- Medical equipment manufacturing industry

- Automotive powertrain system manufacturing industry

- Energy-saving machine manufacturing industry

- Marine machinery manufacturing industry

- Printing machine manufacturing industry

- Agricultural machinery manufacturing industry

- Construction machinery manufacturing industry

- Hydraulic system manufacturing industry

- Pneumatic system manufacturing industry

- Measuring instrument manufacturing industry

- Forming machine manufacturing industry

- Industrial sewing machine manufacturing industry

- Plant production industry

- Fluid machinery manufacturing industry

- Energy industry

- Internal combustion engine manufacturing industry

- Control system manufacturing industry

- Textile machinery manufacturing industry

- Motor manufacturing industry

- Nuclear equipment manufacturing industry, etc.

We will, for example, meet these requests listed below

We use a unique, advanced precision machining technology to respond to the following customers needs:

- As a part of fabless initiative, we want to outsource the medium lot production we have currently operated.

- We want to order the medium lot production of precision/complicated shape parts.

- We are looking for a factory which has high level engineering skills for cross-hole drilling and circular machining of thin materials.

- We need an integrated manufacturing service including material procurement, production, and assembly, as well as quality assurance.

- We are considering placing an order to a factory overseas, but because a direct ordering is difficult, we want to deal with a domestic company with some production facilities overseas.

- We want you to join in prototyping and give a VA/VE proposal to realize a low cost and high precision mass production.

From prototyping to mass production and assembly, we offer a comprehensive service. We can also conduct a post-assembly inspection and provide a total quality assurance.

We have established a large technical & cost competitive advantage. Based on high level process planning ability, we can offer speedy, low-cost mass production of high precision parts.

Further more, we offer a comprehensive service from prototyping to mass production and assembly. We can conduct a post-assembly inspection and provide a total quality assurance.

Nakano Manufacturing phone number for inquiries

+8172-981-0969Service hours: weekdays 9:00-17:00 (closed on Saturdays, Sundays, and national holidays)

- *We will respond to your inquiry as soon as possible.

- *Response may take time depending on the requested information. Thank you for your understanding.

Inquiry via email

To submit your inquiry via email form, please fill in the boxes below and send.

The person in charge will respond to your inquiry as soon as possible.